Air Valves

Air valves play a very significant role in the clean water & wastewater networks.

Air in the pipe network will always create problems. It is causing increased energy consumption for pumping, accelerate corrosion in the pipes, cause inaccurate meter reading and will enforce water hammer when they occur. Pipe network should always be equipped with air valves on strategic places where air will accumulate, typical on the high points of the network.

The problems caused by air in pipelines are well documented and include but are not limited to;

- Reduced pump efficiencies

- Increased energy costs

- Noise and vibration

- Lower flow rates

- Problems with PRV’s and other flow control equipment

- Surges and water hammer problem

- Increased corrosion potential.

Because of these problems, air should be removed from pipelines as quickly as possible when filling or recharging the main after maintenance. This is also equally true for allowing air into the system should there be a conduit break. AVK offers various solutions for energy saving for water pipeline systems.

Correct air valve selection provides protection from transient pressures and entrapped air in pipelines – the main causes for the bursting, collapsing, and fracturing of pipelines. These negative effects on the pipeline assets can be directly associated with reduced pipeline efficiency, premature failure and reduced whole life costs.

However, sometimes the value of these valves in the system is underestimated resulting in neglect or being closed off and not allowed to do their job to protect the network and offer the efficiency gains they were planned for. Wrong air valves selection also can result in many performance and efficiency problems.

Top performance, minimum maintenance and high durability are the characteristics of AVK’s wide range of automatic air valves, air and vacuum valves and combination air valves.

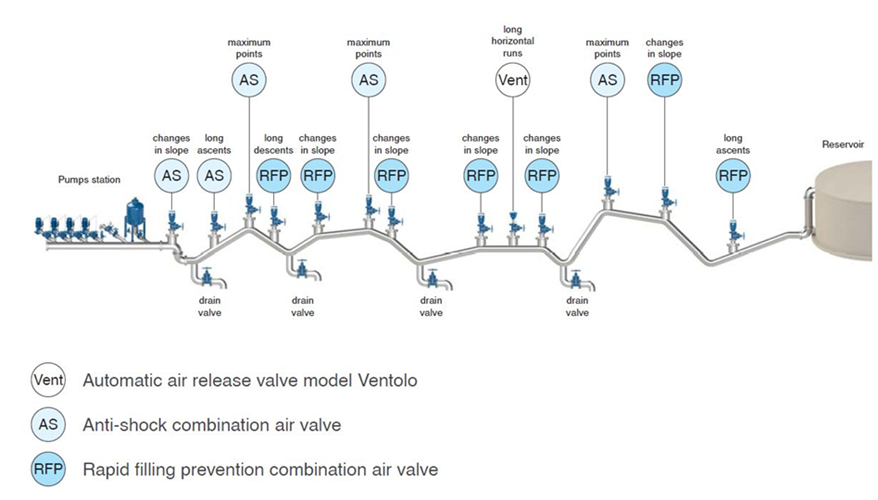

In the figure below you will find the most important locations for air valves on the pipeline with different functions :