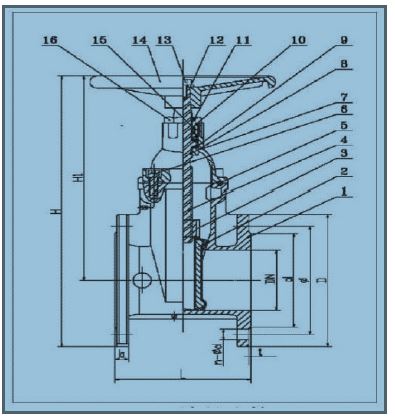

Gate Valve Model No. (GVU101) - F4 Type Non-Rising Stem - Flanged Joints Ends - Resilient Wedge Gate Valves - PN10/16

* Design: DIN 3202 PN10/16.

* Face to face: According to DIN : 3202 F4 , Raised Face

* Temperature: max.80°C.

* Closing: Clockwise Direction.

* Gate Valve model GVU101 is approved by WRAS

* Nominal Pressure: 10/16 Bar .

* Shell Test: 24 Bar for PN16 & 15 Bar for PN10

* Seat Test: 18 Bar for PN16 & 11 Bar for PN10

* Sealing : Triple O-Ring Sealing

→ Coang Material as per BS EN 14901 includes provisions to ensure that the materials are safe for use in contact with drinking water

and meet environmental and health safety standards.

→ Surface Profile: Aer shot blasng, the surface of the ducle iron should have a proper profile (roughness) that allows the coang to

adhere effectively. The profile can be checked with a surface profile gauge to ensure it meets the requirements.

→ Moisture and Contaminants: Once the surface is cleaned, it should be free of moisture, oil, and any remaining debris. Any

contaminants can affect the coating’s performance.

* Shoot Blasting : Shoot Blasting Procedure as per ISO 12944-4, Shot blasting is a surface treatment technique that uses high-speed,

abrasive particles, known as “shots,” to clean, strengthen, or polish ductile iron surfaces. Powerful rainstorm of tiny steel balls particles

striking a surface; each impact helps to remove surface contaminants, such as rust or old paint, and create a uniform, textured finish

that improves the surface’s fatigue strength and wear resistance.

* Coating : Coating procedure as per EN 14901 Fusion Bonded Epoxy coating refers to a type of protective coating typically used in

industrial and commercial applications. It is a high-performance coating made from a blend of epoxy powder that, when applied,

undergoes a process called fusion bonding, which creates a durable, tough, and corrosion-resistant finish.

* Application: For water and neutral liquids and treated MADE IN SAUDI ARABIA

sewage water.

RVK

Gate Valve Model No. (GVU101) – F4 Type

Non-Rising Stem – Flanged Joints Ends – Resilient Wedge Gate Valves – PN10/16

* Connection: Flanged Ends According To EN1092-2

* Protection: To be Epoxy Fusion Bonded inner & outer coating with

minimum thickness of 300 microns approved by WRAS. (Blue Color)

* Wedge: To be fully vulcanized and EPDM rubber and equipped with

wedge shoes to provide smooth operation with zero leakage.